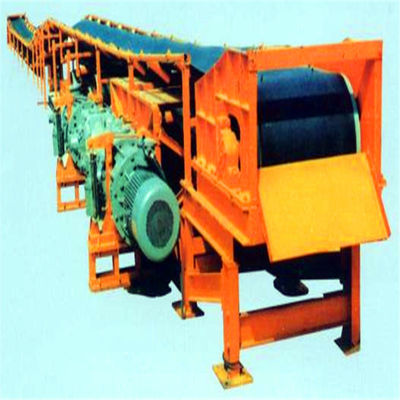

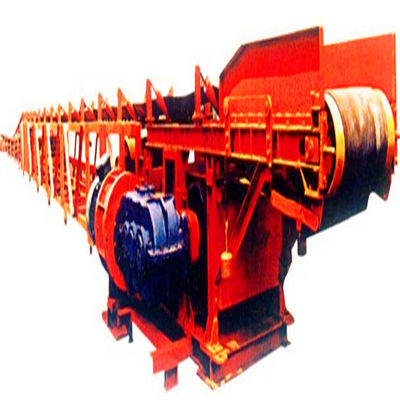

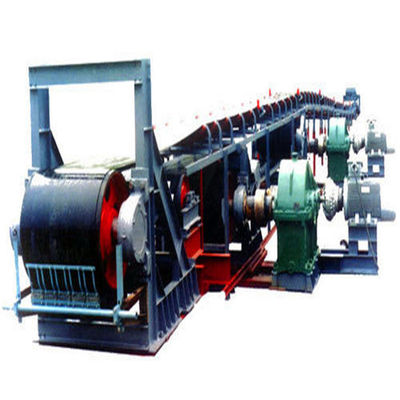

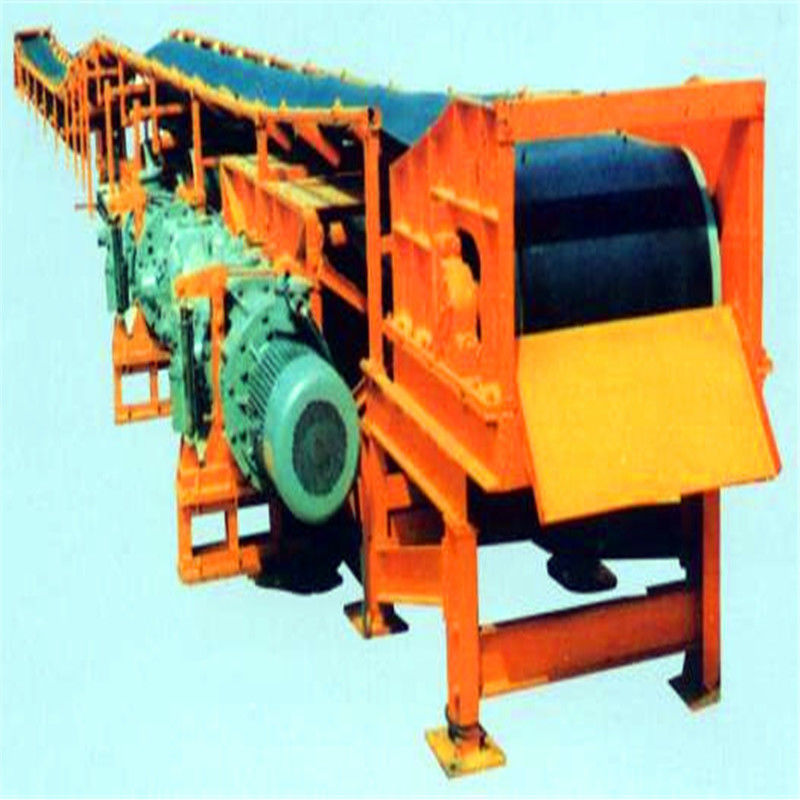

PPG Customized Telescopic Conveyor Belt System For Bulk Material Handling

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI |

| Certification: | mill certificate |

| Model Number: | customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | USD 10000-60000 |

| Packaging Details: | nude |

| Delivery Time: | 120 days |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 220 set/ year |

|

Detail Information |

|||

| Description: | Telescopic Belt Conveyor | Color: | Orange |

|---|---|---|---|

| Type: | Telescopic Conveyor | Painting: | PPG |

| DFT: | 180um | Motor: | Seimens |

| Components: | Top Brand | Character: | Width |

| Highlight: | PPG Telescopic Conveyor Belt,Bulk Material Handling Belt Driven Conveyor,Customized Telescoping Conveyor System |

||

Product Description

Customized telescopic conveyor belt for bulk handling material Heavy-duty telescopic belt conveyor

Shanghai Sunshine industry technology co., Ltd has been designing and supplying client bulk materials conveying systems for industries around the world for the past six years. Whether you are looking for a piece of equipment or a complete turnkey system, we are happy to offer you a customized solution, just customized to your specification requirement. We can provide bulk material handling systems for both new projects and existing systems. It`s used for handling comment material such as coal, clinker, aggregates, biomass products grain gypsum, iron ore, limestone, sulfur.

How to use

Step 1: move the conveyor to the loading place; Step 2: move the conveyor to the inside of the carriage; Step 3: turn on the power supply and turn on the switch for operation. The side switch is the reverse switch, the front button is the start switch, the red light is the power indicator, and the display is the counting display device (there is a small button on it to reset the count to zero.); Step 4: according to the operation requirements, adjust the head height through the hydraulic device, pull the hydraulic controller outward, the head will rise, pull it inward, and the head will fall. Note: pull the controller slowly when descending; Step 5: after the operation is completed, unplug the power, turn off the switch, and then move to the designated place for placement

specification of standard telescopic conveyor belt

|

Width (mm) |

Telescopic device | Telescopic stroke(mm) | Walking speed(M/s) | Walking time(s) | Driving device | notes | ||

| Electric vehicle | reducer | brake | ||||||

| B=1400 | 2 | 3450 | 0.0085 | 40.6 |

Y112M4 4KW 1440/min |

XWE4-95 I=187 |

TJ2-200 1.6dan-m |

High support structure |

| 3 | 6200 | 0.085 | 73 |

Y112M4 4KW 1440/min |

XWE4-95 I=187 |

TJ2-200 1.6dan-m |

Floor type structure | |

| B=1200 | 2 | 3050 | 0.085 | 35.9 |

Y112M4 4KW 1440/min |

XWE4-95 I=187 |

TJ2-200 1.6dan-m |

High support structure |

| 3 | 5700 | 0.085 | 67 |

Y112M4 4KW 1440/min |

XWE4-95 I=187 |

TJ2-200 1.6dan-m |

Floor type structure | |

| B=1000 | 2 | 2800 | 0.085 | 32.9 |

Y112M4 4KW 1440/min |

XWE4-95 I=187 |

TJ2-200 1.6dan-m |

High support structure |

| 3 | 5450 | 0.085 | 64 |

Y112M4 4KW 1440/min |

XWE4-95 I=187 |

TJ2-200 1.6dan-m |

Floor type structure | |

Applications

Case1

![]()

Case2

![]()

Photos of our factory

![]()

![]()

![]()

![]()