Heavy Duty Slewing Cantilever Stacker For Bulk Material Storing And Blending

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI |

| Certification: | manufacture certificate |

| Model Number: | Customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | US $500,000-1,000,000/ Set |

| Packaging Details: | Wooden case or bare |

| Delivery Time: | 6 months after receipt of advance payment |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 40 sets / year |

|

Detail Information |

|||

| Capacity: | 2000 T/h | Product: | Stacker |

|---|---|---|---|

| Painting: | PPG | Color: | Orange |

| Motor: | Seimens | Steel Structure: | SA2.5 |

| Character: | Reliable | Material: | High Quality Steel |

| High Light: | Bulk Material Handling Stacking and Reclaiming Equipment,Heavy Duty Stacker and Reclaimer,Cantilever Stacker Industrial Handling Equipment |

||

Product Description

Heavy duty Slewing Cantilever Stacker for Bulk Material Handling Slewing Cantilever Stacker

The slewing cantilever stacker is mainly used for stacking limestone, sandstone, raw coal and other bulk materials. It is mainly used for storing and blending materials in stockyard. It is mainly applicated for metallurgy, mining, building materials, chemical industry, cement and other industries.

Feature

The slewing cantilever stacker has the advantages of simple structure, reliable performance, easy operation, convenient maintenance and safe operation.

The slewing cantilever stacker can stacking operation to different material pile, and to stack a variety of materials, meet different stacking processes requirement. The slewing cantilever stacker was design as compact, electric-hydraulic driven with automatic operating function without man power.

Composition

The slewing cantilever stacker can stacking operation to different material pile, and to stack a variety of materials, meet different stacking processes requirement. The slewing cantilever stacker was design as compact, electric-hydraulic driven with automatic operating function without man power.

Working principle

The bulk materials are unloaded to the cantilever belt conveyor via the feeding belt conveyor and feeding system of stacker. And then transferred to the stockyard by the cantilever belt conveyor. In the stackyard area, the stacker can stack materials to form into zigzag, conical and trapezoidal material piles through actions by traveling, slewing and luffing.

Specification of Slewing Cantilever Stacker

| description | parameter | unit |

| material | limestone,sandstone,raw coke | |

| density | 0.8~2.2 | t/m3 |

| granularity | <70 | mm |

| moisture | <2 | % |

| stacking capacity | 100~5000 | t/h |

| rail span | 4~8 | m |

| length of cantilever | 15~40 | m |

| width of belt | 500~1800 | mm |

NOTICES

The customer shall provide the following information when place order

- character of bulk material;

- Stockyard information;

- Process flow chart;

- Power supply;

- Communication and control requirements.

Applications

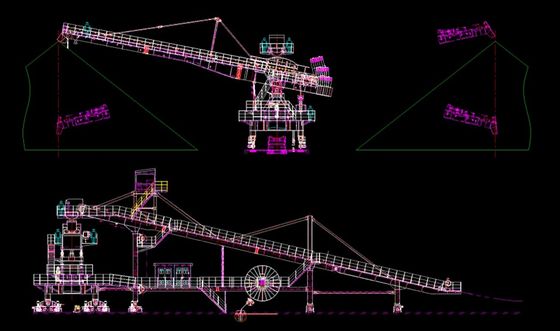

Case1

![]()

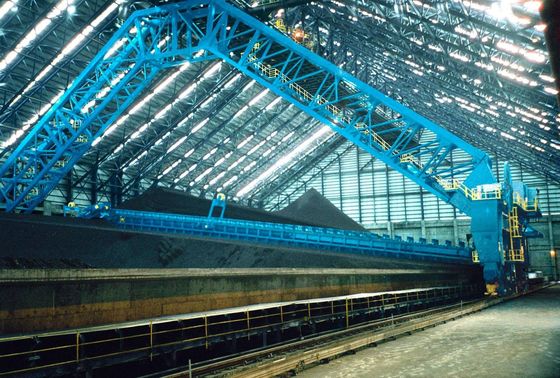

Case2

![]()

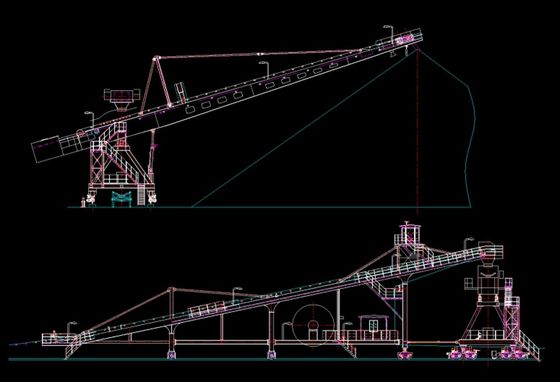

Photos of our factory

![]()

![]()

![]()

![]()