Bag Filter Dust Controlled Eco Hopper For Bulk Materials Handling

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI |

| Certification: | mill certificate |

| Model Number: | 60 cube meter |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | USD 200000 |

| Packaging Details: | nude |

| Delivery Time: | 90 days |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 85 set/yesr |

|

Detail Information |

|||

| Product: | 60m³ Eco Hopper | Color: | Grey |

|---|---|---|---|

| Type: | Bag Filter Dust Controlled | Painting: | PPG |

| Welding: | According To AWS | Model: | Customized |

| Character: | Self-propelled | Application: | Coal Handling |

| High Light: | Dust Controlled Unloading Hopper,Bag Filter Eco Hopper,Bulk Materials Unloading Hopper |

||

Product Description

Dust controlled Eco hopper with bag filter for bulk materials handling

The SSI ECO hopper is designed as a dust controlled, grab or belt conveyor unloading hopper, is an economical and ecologically sensitive solution. It`s customized designe to suit the property of any bulk materials. And fulfill all needs for the efficient import of dry bulk materials.

The SSI ECO hoppers is designed base on the client`s specification requirement.

The Eco hopper is devided into an upper and lower section, separated by a dust retention. Integral reverse jet filters are positioned around inlet to extract and clean the dust laden air. Collected the dust is then recycled into the main stream of material.

The environmental protection dust controlled hopper, which comprises a hopper support and a hopper body with a valve and a material guide groove under it. The hopper support is also provided with a dust controlled component, and the dust suction port of the dust controlled component is located directly above the ground belt conveyor The utility model has the advantages that during the whole conveying process from the hopper outlet to the ground belt conveyor, the powdery materials are transported at a slow speed, and the dust removal components are added to absorb the scattered dust, which can greatly purify the air at the transportation site, ensure that the loading and unloading dust does not leak out and protect the environment

Technical specification

| output | 500t/h |

| material | cement /coal |

| density | 0.83t/m³ |

| volume | 40m³ |

| application | discharge to truck |

| pressure on each support landing | 30t |

| full load of hopper | 80t |

| size of discharge opening | 400mm*400mm |

| power of fan motor | 22kw*3 |

| noise | less than 80 DB |

| travel speed | 10m/min |

| power consumption | 105kw |

| dead weight | 75t |

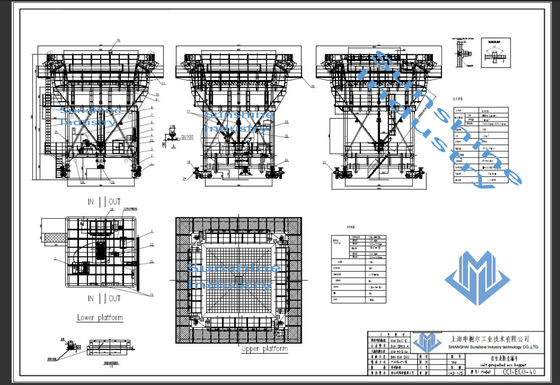

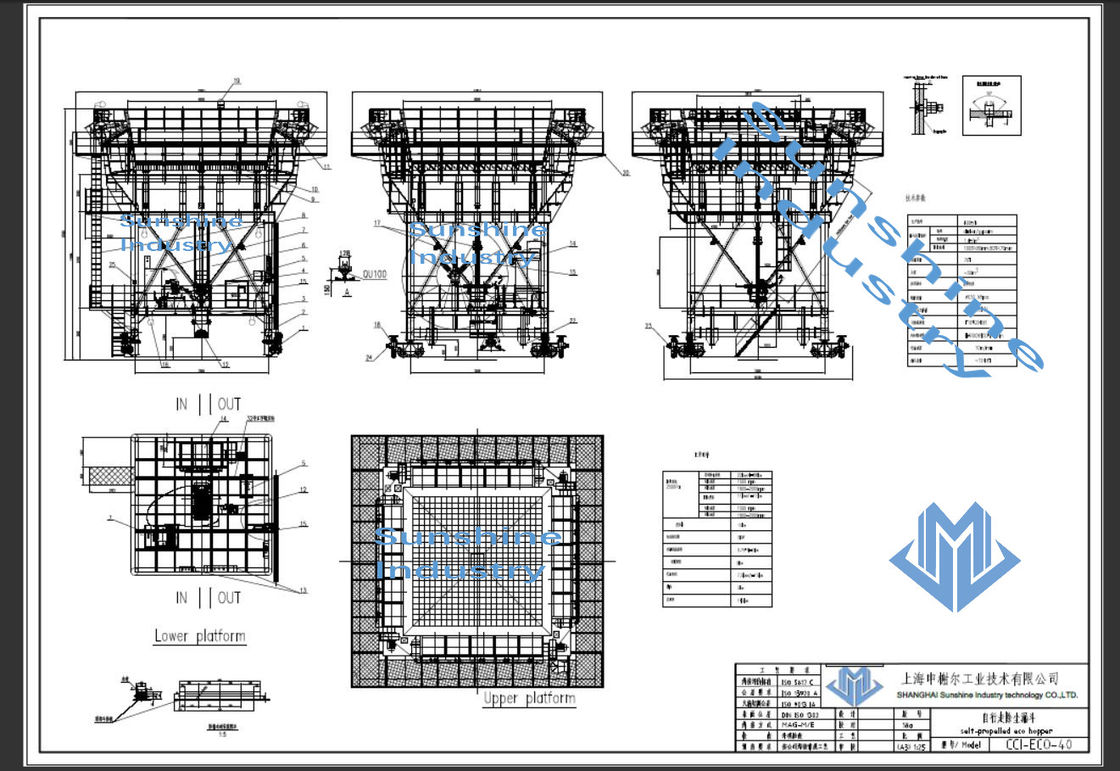

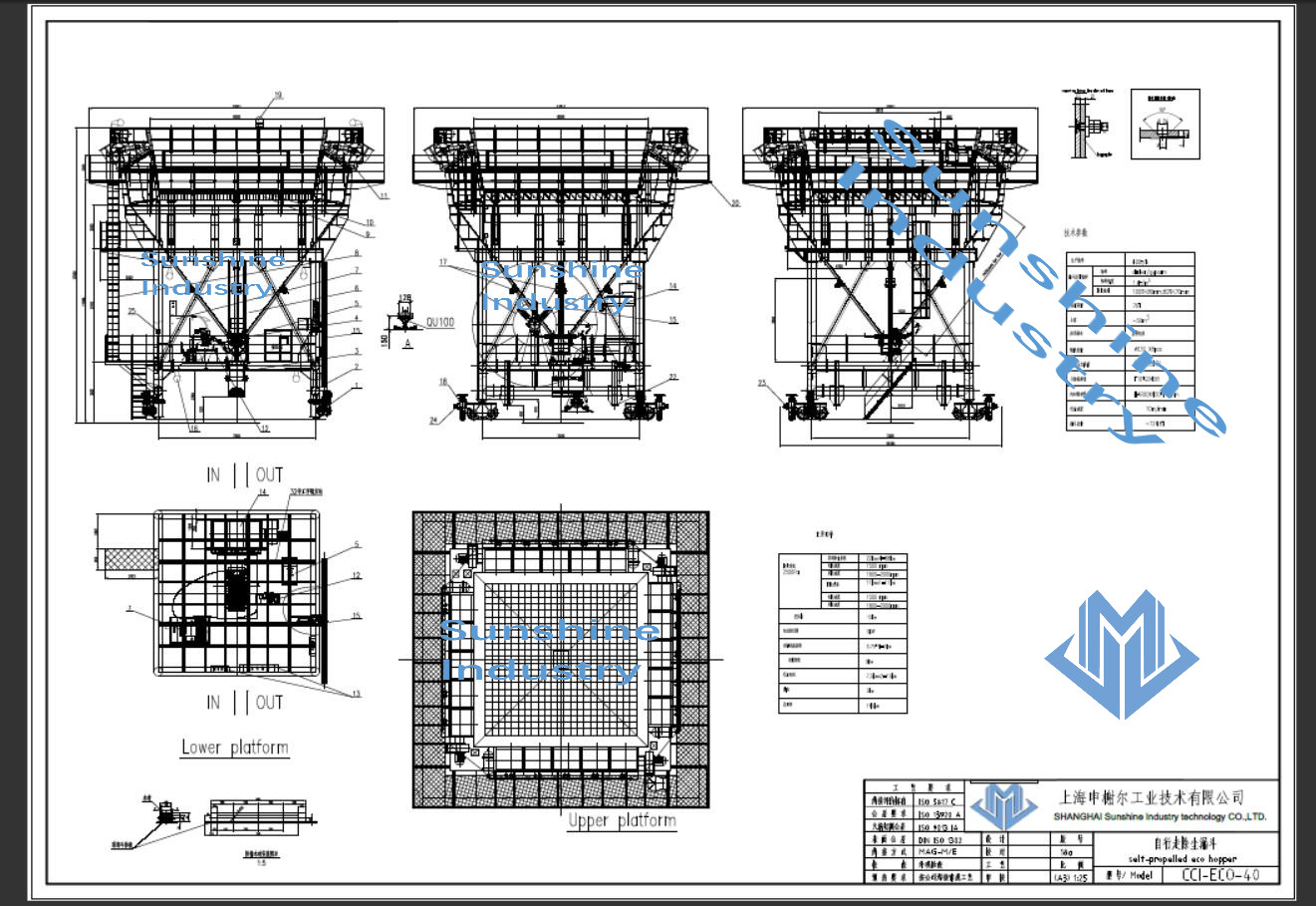

General drawing

![]()

Photos of our factory

![]()

![]()

![]()

![]()