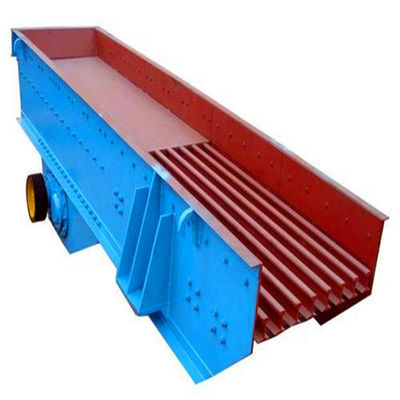

Heavy Duty Apron Feeder For Large Lump Bulk Materials Handling

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI |

| Certification: | mill certificate |

| Model Number: | SSI-500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Packaging Details: | nude |

| Delivery Time: | 90 days |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 200 set/year |

|

Detail Information |

|||

| Product: | Weight Feeder | Color: | Red |

|---|---|---|---|

| Painting: | Jotun | Type: | Weighing |

| Capacity: | 500t/h | DFT: | 220um |

| Application: | Mining | Character: | Durable |

| High Light: | Large Lump Materials Apron Feeder,Bulk Materials Handling Apron Feeder |

||

Product Description

Heavy-duty apron feeder for large lump bulk materials handling

The possibility of combining material extraction from the hopper, weighing, and metering in one machine. For application where usage of belt weigh feeder is not possible.

SSI vibrating feeders are ideal for direct feeding processing machinery such as roller crusher, cone crusher, jaw crusher, impact crusher, and hammer crusher. The feeders can be also used to feed screens, roller sizers, and conveyor belts. All the feeds can be designed based on the specification of the client`s requirement.

Full preassembly and calibration are provided in our factory.

A wide range of bulk materials is suited to apply to the SSI feeder.

Technical specification

| Model | A | B | C | H | H1 | H2 | H3 | L | L1 | L2 | L3 | L4 | S | S1 |

| K-0 | 1360 | 3100 | 846 | 210 | 416 | 325 | 1051 | 2450 | 840 | 1000 | 800 | 750 | 1040 | 750 |

| K-1 | 1360 | 3100 | 1112 | 210 | 416 | 325 | 1051 | 2450 | 840 | 1000 | 800 | 750 | 1040 | 1000 |

| K-2 | 1360 | 3540 | 1112 | 208 | 684 | 325 | 1297 | 2850 | 1150 | 1250 | 1050 | 1000 | 940 | 1000 |

| K-3 | 1352 | 3950 | 1360 | 250 | 640 | 345 | 1341 | 3270 | 1400 | 1500 | 1300 | 1250 | 1157 | 1250 |

| K-4 | 1622 | 4740 | 1632 | 330 | 762 | 345 | 1534 | 3850 | 1700 | 1750 | 1550 | 1500 | 1435 | 1500 |

| C | D | E | F | G | H | J | K | L | |

| B32-75 | 163 | 810 | 529 | 710 | 1030 | 480 | 150 | 492 | 280 |

| B40-100 | 229 | 1033 | 594 | 761 | 1280 | 520 | 150 | 610 | 330 |

| B50-100 | 251 | 1060 | 681 | 823 | 1320 | 520 | 160 | 710 | 415 |

| B63-100 | 262 | 1042 | 693 | 837 | 1330 | 290 | 180 | 845 | 545 |

| B80-125 | 368 | 1325 | 785 | 967 | 1670 | 590 | 200 | 1066 | 705 |

| B100-150 | 392 | 1586 | 924 | 1190 | 1950 | 800 | 260 | 1318 | 870 |

| B125-150 | 389 | 1589 | 1028 | 1391 | 1950 | 900 | 300 | 1568 | 1075 |

| B160-1750 | 492 | 1824 | 1180 | 1398 | 2450 | 1100 | 400 | 1984 | 1350 |

Overall dimension

![]()

![]()

About us

Shanghai Sunshine Industrial Technology Co., Ltd. takes the development of precision manufacturing capability as its strategic goal, integrates design capability and manufacturing capability, designs professional equipment and systems for handling various dry bulk cargoes, and specializes in manufacturing large and medium-sized precision parts for the equipment. Shanghai Sunshine has excellent R & D and design ability of bulk cargoes conveying equipment and integrates the outstanding manufacturing capacity and years of rich manufacturing experience of Tonglu Fuchunjiang Power Generation factory. Shanghai Sunshine has strong technical ability and production ability with high quality and low labor price. Our load and unload equipment includes a train tipping machine, ship unloader, ship loader, etc. Our conveying equipment includes a belt conveyor, screw conveyor, chain bucket conveyor, scraper conveyor, inner bypass low-pressure dense phase pneumatic conveying system, etc. And our storage equipment includes bucket wheel stacker reclaimer, harrow reclaimer, scraper conveyor, etc. In addition, Shanghai Sunshine also provide parts and welding steel structure for heavy equipment.

Photos of our factory

![]()

![]()

![]()

![]()