600tph Capacity Stockyard Stacker And Reclaimer For Bulk Material

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI-HDCZ |

| Certification: | manufacture certificate |

| Model Number: | Customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | US $500,000-5,000,000/ Set |

| Packaging Details: | Wooden case or bare |

| Delivery Time: | 6 months after receipt of advance payment |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 40 sets / year |

|

Detail Information |

|||

| Product: | Stockyard Stacker And Reclaimer | Painting: | PPG |

|---|---|---|---|

| Color: | Red | Capacity: | 600 T/h |

| Motor: | European Brand | Power Source: | 380v 50hz |

| Steel Work: | High Quality Steel | Material Handling: | Coal |

| Highlight: | 600tph Stacker And Reclaimer,Bulk Material Portal Stacker Reclaimer |

||

Product Description

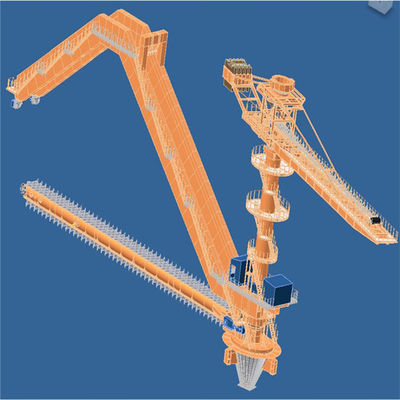

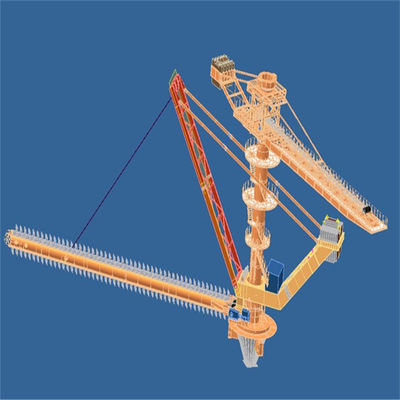

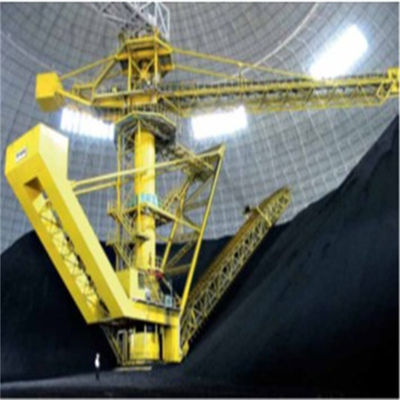

600tph capacity stockyard stacker and reclaimer for bulk material stacking and reclaiming

Circular gantry scraper stacker and reclaimer is mainly used in building materials, coal, metallurgy, electric power, port, and other industries, and is mostly used to stack limestone or coal and other bulk materials. The cantilever of the stacker is equipped with a belt conveyor, which passes through the steel structure grid roof of the circular stockyard from the belt conveyor on the trestle, and the input materials complete the ring conical stacking through the belt conveyor on the cantilever of the stacker; The reclaimer completes the reclaiming work via three linking processes: traveling system, luffing system, and scraper system. The scraper reclaimer scrapes the materials into the conical hopper under the central column along the slope of the pile and outputs the materials through the vibrating feeder and underground belt conveyor.

![]()

Feature

| product | Stacker and Reclaimer |

| painting | PPG |

| color | red |

| capacity | 600 t/h |

| character | heavy duty |

| advantage | robust design |

| benefit | low maintenance |

| material handling | coal or limestone |

Main components of circular stacker and reclaimer

1. Stacking steel structure, cantilever belt conveyor

The cantilever stacker takes the central column as the center, one end is the belt conveyor with cantilever steel structure, and the other end is the counterweight box. The middle stacking slewing part is connected with the central column by slewing bearing, and the stacker can rotate by meshing the pinion on the slewing driver with the gear on the central column. The materials entering the circular stockyard are unloaded at the head of the cantilever belt conveyor and directly stacked to the stockyard. The stacker rotates at a certain angle for slope stacking until it is stacked into an annular pile.

![]()

There are two main structural types of cantilever stacker, cantilever fixed type and cantilever luffing type.

Comparison of the two types of stackers:

(1)The advantages of the fixed stacker are simple structure and low cost. The disadvantage is that when the lower part of the stacker is not stacked or the material pile is low, the difference is huge, and the dust in the stockyard is more serious (even with a spray system).

(2)The luffing stacker uses the hydraulic cylinder to raise or lower the cantilever. Its advantage is cantilever can raise up and down according to the stacking height to reduce the material drop and avoid dust flying. As well, it can reduce the height of the central column and reduce the cost. The disadvantage is that the structure is more complex.

![]()

2. King column and slewing mechanism of circular stacker and reclaimer

(1) The king column of the stacker reclaimer is located in the center of the circular stockyard. It is an important component of the stacker reclaimer. It not only bears the load of the main components and the input trestle but also is the installation center of the components. Therefore, its manufacturing and installation process requirements are very high. It is made of steel plate rolled into a cylindrical shape and welded and assembled. The utility model is provided with a stacking steel structure, a rolling bearing for the stacking rotary part, and a cable drag connecting various equipment components

(2)The top of the king column is the stacking rotary part, the upper part of which is connected with the belt conveyor trestle entering the circular stockyard through the rotary bearing and serves as a support point for the trestle load, and the lower part is connected with the middle column through the rotary bearing.

(3) To enable the slewing bearing device to bear large vertical force, horizontal force, and overturning moment, the slewing bearing support type is adopted. The rotary bearing is protected by a dust cover. Its structure can adapt to the harsh working environment and has the functions of dust prevention, water immersion prevention, refueling, cleaning, and maintenance.