Longitudinal Stockyard Scraper Reclaimer For Coal Reclaiming

Product Details:

| Place of Origin: | china |

| Brand Name: | SSI-ZHIGO |

| Certification: | manufacture certificate |

| Model Number: | customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | US $500,000-1,000,000/ Set |

| Packaging Details: | Wooden case or bare |

| Delivery Time: | 4-6 months after receipt of advance payment |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 40 sets / year |

|

Detail Information |

|||

| Item: | Gantry Scraper Reclaimer | Capacity: | 1800 T/h |

|---|---|---|---|

| Character: | Durable | Painting: | According To ISO12944 |

| Color: | Advise By User | Advantage: | High Performance |

| Benefit: | Low Cost | Material: | Material |

| High Light: | Coal Reclaiming Bridge Scraper Reclaimer,Longitudinal Stockyard Bridge Scraper Reclaimer |

||

Product Description

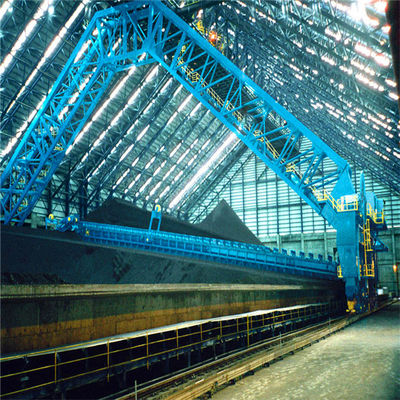

longitudinal stockyard gantry scraper reclaimer Stacking and Reclaiming System for Longitudinal Stockyard

applications

The long stockyard gate scraper reclaimer is widely used in steel, cement, chemical industry and other industries. It is suitable for long stockyards with flexible material stacking and low homogenization requirements.

feature

The equipment is mainly used in the electromechanical integration equipment of environmental protection closed long material storage yard. It has the characteristics of small land occupation, large reserves, large production capacity, low pollution and high degree of automation.

composition

The gantry scraper reclaimer is mainly composed of traveling mechanism, gantry, scraper conveying system, winch system, electrical control room, etc.

Working principle

The gantry scraper reclaimer carries out reclaiming operation on the tracks on both sides of the stockyard. The reclaimer unloads the materials into the guide chute through the scraper reclaiming system and sends them to the discharge belt conveyor for transportation. After each layer of material is taken by the reclaiming arm, the corresponding angle is lowered according to the preset command, and the stack is taken out layer by layer at the set reclaiming running speed.

Table of equipment selection parameters

| description | parameter | unit |

| material | Coal, iron ore, etc | |

| density | 0.8~2.3 | t/m3 |

| granularity | <70 | mm |

| moisture | <2 | % |

| stacking capacity | 200~2000 | t/h |

| Gauge | 20~50 | m |

NOTICES

The customer shall provide the following information when place order:

- character of bulk material;

- Stockyard information;

- Process flow chart;

- Power supply;

- Communication and control requirements.

About us

Shanghai Sunshine Industrial Technology Co., Ltd. takes the development of precision manufacturing capability as its strategic goal, integrates design capability and manufacturing capability, designs professional equipment and systems for handling various dry bulk cargoes, and specializes in manufacturing large and medium-sized precision parts for the equipment. Shanghai Sunshine has excellent R & D and design ability of bulk cargoes conveying equipment and integrates the outstanding manufacturing capacity and years of rich manufacturing experience of Tonglu Fuchunjiang Power Generation factory. Shanghai Sunshine has strong technical ability and production ability with high quality and low labor price. Our load and unload equipment including train tipping machine, ship unloader, ship loader, etc. Our conveying equipment including belt conveyor, screw conveyor, chain bucket conveyor, scraper conveyor, inner bypass low-pressure dense phase pneumatic conveying system, etc. And our storage equipment including bucket wheel stacker reclaimer, harrow reclaimer, scraper conveyor, etc. In addition Shanghai Sunshine also provide parts and welding steel structure for heavy equipment.

Photos of our factory

![]()

![]()

![]()

![]()