Circular Stockyard Stacking And Reclaiming System For Bulk Materials Handling

Product Details:

| Place of Origin: | China |

| Brand Name: | SSI-HDCZ |

| Certification: | manufacture certificate |

| Model Number: | Customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | US $1,500,000-5,000,000/ Set |

| Packaging Details: | Wooden case or bare |

| Delivery Time: | 6 months after receipt of advance payment |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 40 sets / year |

|

Detail Information |

|||

| Project: | Stacking And Reclaiming Equipment | Material: | Limestone |

|---|---|---|---|

| Painting: | HEMPEL | Color: | By User |

| Steel Work: | High Quality Steel | Benefit: | Cost Effective |

| Welding: | GMAW | Capacity: | 1800 T/h |

| High Light: | Stockyard Circular Stacker Reclaimer,Circular Coal Reclaimer Stacker,Bulk Materials Handling Stacker Reclaimer |

||

Product Description

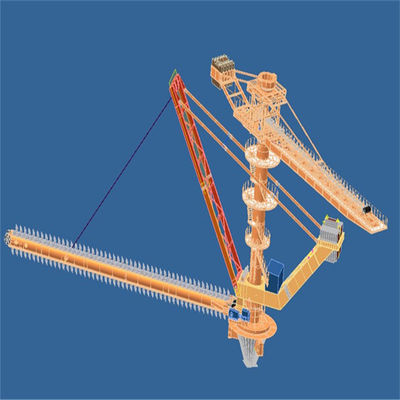

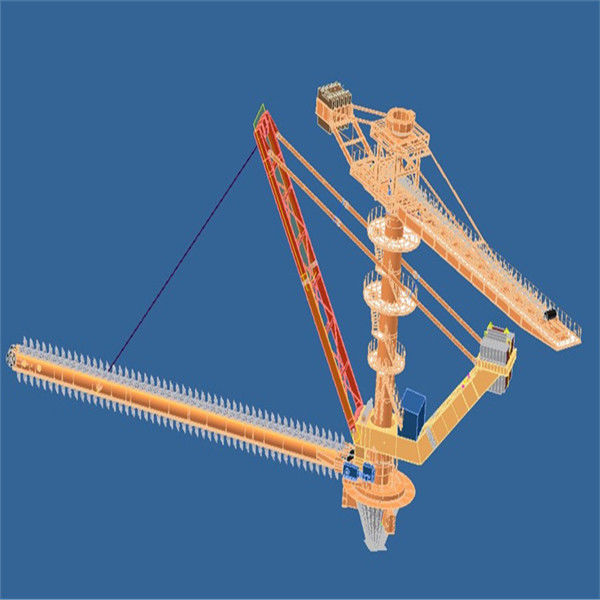

Circular stockyard stacking and reclaiming system for bulk materials handling

Introduction

Circular gantry scraper stacker and reclaimer is mainly used in building materials, coal, metallurgy, electric power, port, and other industries, and is mostly used to stack limestone or coal and other bulk materials. The cantilever of the stacker is equipped with a belt conveyor, which passes through the steel structure grid roof of the circular stockyard from the belt conveyor on the trestle, and the input materials complete the ring conical stacking through the belt conveyor on the cantilever of the stacker; The reclaimer completes the reclaiming work via three linking processes: traveling system, luffing system, and scraper system. The scraper reclaimer scrapes the materials into the conical hopper under the central column along the slope of the pile and outputs the materials through the vibrating feeder and underground belt conveyor.

![]()

Feature

| project | stacking and reclaiming equipment |

| painting | HEMPEL |

| color | by user |

| capacity | 1800 t/h |

| character | heavy duty |

| advantage | low maintenance |

| benefit | low cost |

| application | coal handling |

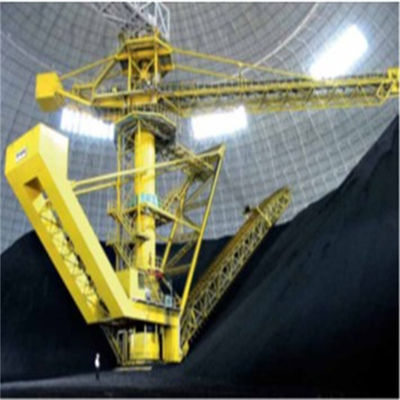

Applications

Case1

![]()

Case2

![]()

![]()

Case3

![]()

Case4

![]()

Case5

![]()

Details

Scraper

![]()

4. Reclaimer luffing mechanism:

![]()

5. Scraper reclaimer

(1) The scraper reclaimer adopts a sprocket to drive the roller chain, and then the roller chain drives the scraper to reclaim. This method has large traction, small linear resistance, and durability. It is a reclaiming method integrating reclaiming and transportation.

(2)The scraper is fixed on the double chain mechanism, and the sprocket is driven by the motor at the rear for circular movement. The scraper scrapes the materials at the lower part of the stacker into the conical hopper at the lower part of the king column.

(3) The scraper adopts the folded plate structure with forwarding inclination on both sides, which is welded by steel plate and has sufficient strength and stiffness. There are scraping teeth on both sides of the scraper. This structure can cut the material laterally most effectively, and the scraper does not stick to the material and has no return. The scraper body and roller chain are connected by high-strength bolts, which are convenient for maintenance and disassembly. The chain can be divided into the built-in chain and external chain according to the placement position of the roller. Compared with the built-in chain, the external chain has the advantages of low noise and maintenance-free

(4)The scraper driving device is composed of a motor, reducer, hydraulic coupling, etc. The driving device is impact-resistant and convenient for maintenance. The driving device is equipped with electrical double safety and overload protection and is equipped with a good shock absorption device.

(5) The tensioning device of the scraper reclaimer is set at the head sprocket. The tensioning device is hydraulic tensioning, with constant tension and easy operation and adjustment.

![]()

9.specification of gantry bucket wheel stacker and reclaimer

![]()

![]()